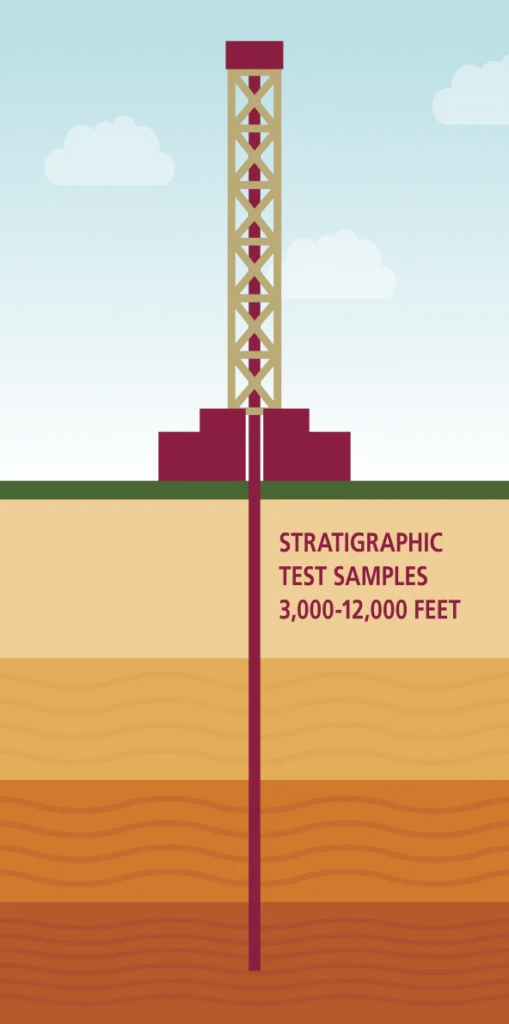

The Tri-State CCS Hub is preparing to drill stratigraphic test wells across the project footprint to gather critical data about the underground geology and its capacity to safely store carbon dioxide (CO2). This important work is part of the development of the project and is being performed in coordination with landowner participants.

What is a Stratigraphic Test Well?

Stratigraphic test wells provide important geologic data about the type and makeup of the rock, formation depths, and porosity and permeability of the pore space, among other things. This data should also provide further confirmation that this location is suitable for the safe, long-term storage of CO2.

Generally, the timeline to prepare the land, drill the test well and perform restoration work spans about 5 months. These activities may appear similar to drilling a well for oil or gas production, but with less truck traffic and less water use. Our goal is to minimize disruption to neighbors and to the community.

Stratigraphic test wells do not inject CO2, and the Tri-State CCS Hub team is not allowed to store CO2 until obtaining all the required permits from state and federal regulators.

Stages of the Drilling Process

Stratigraphic wells are built in stages, each of which serves an important function in maintaining well integrity and environmental safety. These stages include:

The project team creates site-specific well plans; conducts detailed environmental and topographic surveys; obtains necessary permits, such as road use agreements; and coordinates with landowners and community stakeholders.

A stable, graded well pad, typically about 3 acres in size, is constructed to support drilling operations. This pad is reinforced with rock or wooden mats to prevent soil erosion and provide a secure, low-impact work surface for heavy equipment.

An approximately 6 foot x 6 foot x 4 foot lined cellar is excavated to house wellhead equipment and provide a secure foundation for drilling and well control. This infrastructure supports the early stages of well construction and ensures long-term well stability.

The surface hole is drilled to stabilize the borehole and allow for safe sampling. Depending on site needs, limited casing and cement may be used to support well integrity during data collection. These wells are not built for CO2 injection.

Comprehensive data collection is conducted to verify well integrity, assess formation properties and confirm the site’s suitability for long term CO2 storage. This includes pressure testing, fluid sampling and rock property analysis, which provide insights into subsurface conditions and help ensure long-term storage security.

After data collection is complete, the well will be retained for longterm monitoring. During this period, sensors and periodic testing may be used to monitor well integrity, pressure changes and any fluid movement. This helps confirm that the site remains geologically stable and suitable for future CO2 storage. Once monitoring obligations are met and closure criteria are satisfied, the well can be permanently closed in coordination with regulatory agencies.

Example of core samples obtained from stratigraphic test wells.

Our Commitment

Our team is committed to working with area leaders, landowners and community members to create a CCS project that is safe and mutually beneficial.

The use of underground pore space for CCS has been in practice for decades. The process is gaining in use as CO2 emitters – ethanol plants, manufacturers, industrial producers, power plants – seek an efficient means to respond to environmental regulations and climate mandates. CCS is a solution to help these businesses remain stable regional employers and taxpayers.